From right to left: ALGAplus CEO, Helena Abreu, at the outdoor facilities. An employee working in the maternity room. Photos: © Alfonso Ré Lau and ALGAplus.

ALGAplus is a Portuguese company that farms organic certified seaweed in a land-based facility, an alternative to wild harvesting which is still the origin of most of the seaweed in Europe. Within our III Annual Meeting in Porto, all AquaVitae members were invited to visited ALGAplus facilities in Ílhavo. The visit was guided by the co-founder and the managing director of the company, Helena Abreu.

The beginning

The concept was developed in 2006, by two biologists, during their PhD thesis. After the creation of all concept, completely pioneer in Europe, the company was created 5 years later in 2011 and the seaweed farming started in 2012.

One of the first difficulties was to find the perfect location to the company, considering the establishment of the IMTA concept. Luckily, the eldest fish farmer in the region opened his doors to this project, in which he believed in. With his faith and support ALGAplus became one of the most important macroalgae producers in Europe.

At the beginning of its activities, ALGAplus only has three employees. Today the company counts with 18 employees, plus academic interns. ALGAplus invests in training and in the students that develop internship in the company. Besides, ALGAplus is the first job of many young people, being the average age of the employees 32 years old.

In 2021, ALGAplus was able to increase its capital. Abreu states this was necessary to “upscale production, and improvement of the processing and labor conditions to our workers”.

The facility

ALGAplus facilities are located in Ria de Aveiro, coastal lagoon of Portugal, in a 14 ha property. Abreu let us know that “We are at a Natura 2000 site, meaning it is an ecological reserved area, and everything here has to follow restricted rules.”

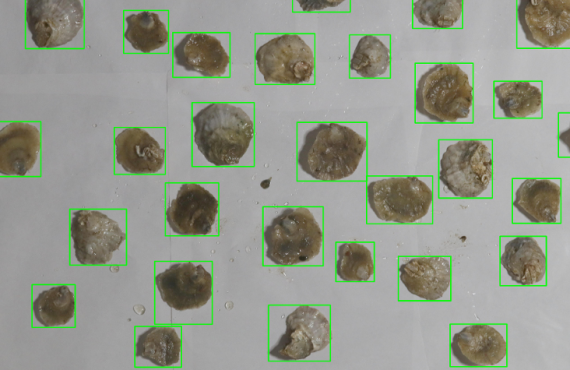

The most sensitive and “baby seaweed” species, being cultivated at ALGAplus, start their journey in the maternity. Under the care of maternity technicians, seaweed is continuously upscaled until ready to be transferred to the outdoors tanks. In this space, the team also performs research trials, biobanking, domestication of new species and quality controls.

Helena Abreu showed us two 15 m2 tanks with Gracilaria sp. and Palmaria palmata. The majority of the seaweed production is made using a free-floating system and the nutrients are insured by the metabolism of the fish (seabass and seabream) that grows in ponds also in the property.

The process

After the harvesting of the seaweed from the ponds, the seaweed is pre-processed. At this stage, ALGAplus mainly sells seaweed as a fresh product, fresh with salt to increase the self-life of the product, dried or frozen. It will depend on our customers need or final application. In the end, the product is sent to the final costumer or restaurants, retails, food, and cosmetic companies.

Philosophy

Circular economy is a central aspect in ALGAplus’ production. The company is working on an entire chain of environmentally friendly processes: all the way from the production to packaging. ALGAplus relies on natural resources such as the sun, the water from Aveiro lagoon and an IMTA system. The IMTA increases the techno-economic and environmental sustainability of the company, and improves the final product quality that is farmed without artificial fertilizers.

Working beyond Aveiro

ALGAplus collaborates with different universities, namely in the context of different financed projects, such as CIIMAR in the context of AquaVitae project. This particular collaboration intends to optimize of cultivation protocols of Ulva and Codium, and also the knowledge exchange with other companies/researchers, specifically from South Africa and Brazil.

The company exports more than a half of its business volume to Europe, but also reaching USA, Canada and Australia. ALGAplus has created its own brands that represent 15% of its business volume, mostly sold in Portugal.

“This way we have changed mentalities and promoting the consumption of seaweed also here in Portugal. We feel that we are more integrated in the local, in the national communities and it has been a way of attracting traditional food companies and also feed and cosmetics into this resource that can be locally produced here in Portugal, in Europe, instead of importing it from Asia which is still mostly coming”, ensures Helena. ALGAplus was born to supply EU farmed seaweed of high quality to the word and promote its consumption.

Species

ALGAplus’ main species are Ulva sp, Codium tomentosum, Gracilaria sp., Porphyra dioca and P. umbilicalis (also known as Atlantic Nori), taking between 2 and 28 weeks to growth accordint to the species. ALGAplus is implementing new production systems that will allow the company to reach 160 tons of fresh seaweed per year.

In Japan, over 450 seaweed species are consumed while in Europe only 21 are accepted, “but this is going to change shortly” as reviewed in the recent scientific paper “Mendes et al, Algae as Food in Europe: An Overview of Species Diversity and Their Application, Foods, 2022”, Abreu argues.

Learn more:

–Algae: a solution for the future that we can implement in the present

–Case Study 1 is lead by CIIMAR counting on ALGAplus support