Biosensor to monitore sulphite process in shrimp aquaculture – Photos: BIOLAN

By Jone Garate, (PhD in Chemistry), Development and Validation Department in Biolan

One of the most important challenges of food industry is to prevent contaminated products from reaching the market. Unsafe food containing bacteria, viruses or chemical substances can cause more than 200 different diseases. Traditional analytical methods applied to food safety monitoring are time consuming, expensive and require the use of dangerous chemicals.

What is a biosensor and how are they applied to food safety testing?

Biosensors are systems that incorporate a biochemical sensing element (enzyme) immobilized on a transducer system that relates the concentration of the analyte to a measurable signal. The addition of the analyte causes the sequential redox reactions that involve the release of the electrons proportional to the concentration of the analyte. The specificity, high sensitivity, speed and possibility of digitalization and their capacity to work in real time are the most important characteristics of these devices to be competitive with other technologies in the detection of parameters related to food safety.

Why is sulphite a food safety issue in shrimp aquaculture?

Sulphites are an antibacterial and antioxidant in food and beverage sector. They are used to extend the shelf-life of products and to maintain product colour in a wide variety of food, such as dried fruits, meat or shrimp.

However, they are recorded as allergens by the main international regulatory bodies on food safety because of their adverse health effects. For this reason, sulphites maximum concentration is regulated and it must be ensured by the agro-food processing industries. In Europe, the limit of sulphites in crustaceans is restricted from 150 to 300 mg/kg, according to the size of the crustacean.

The addition of sulphites in raw prawns and shrimps have been a world-wide practice for many years to avoid melanosis, a natural postmortem mechanism that involves the action of an enzyme, which in the presence of oxygen forms compounds that polymerize into insoluble pigments or blackspots.

It is harmless, it has no impact on product taste and it is not an indicative of bacterial spoilage, but it can drastically affect consumer acceptability of the products and diminish their market value. Shrimp farms use this antioxidant at the harvest time, mainly metabilsulphite, in order to inhibit this enzymatic process.

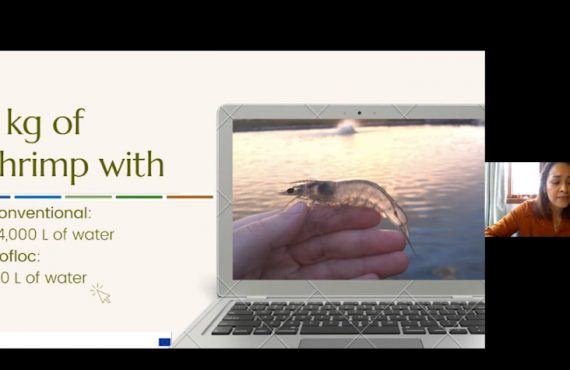

One of the process steps for the manufacture of screen-printed electrodes on which sulphite biosensors are based

Shrimps are harvested in large farms where they must be chilled as soon as possible once they are removed from the pond. Then, the traditional treatment consists of taking the cooled shrimp and immersing them in a metabisulphite solution for several minutes. Uncontrolled addition of this antioxidant leads to high number of sulphite analysis over shrimp, which implies high cost for the processing plants, especially taking into account how tedious and time-consuming the Monier Williams procedure is,the official method of analysis . Therefore, there is a need to control sulphites over the whole process in an accurate and fast way.

How are BIOLAN biosensors modernizing sulphite testing process in shrimp aquaculture?

BIOLAN has developed a handheld biosensor for sulfite monitoring in water where the crustaceans are treated. In the frame of AquaVitae project, BIOLAN is optimizing the biosensor through the application of System on Chip electronics and IoT in order to develop a digital cloud-enabled biosensor. This portable device, which requires minimal sample treatment, is suitable for field applications to monitor sulphite concentration in less than a minute in shrimp farming and ensure the right amount of metabisulphite in water bins. The optimized biosensor provides accurate sulphite quantification from 8 to 110 g/L of metabisulphite, a repetitivity expressed as an imprecision lower than 7%, and as an irreproducibility lower than 10%.

Next steps are focused on the integration of this innovative biosensor into cloud with benefits that could allow to increase sulfite content monitoring points, have full data traceability and integrity along the supply chain, share information as quick as possible to decision makers, secure data storage and save time in data handling.

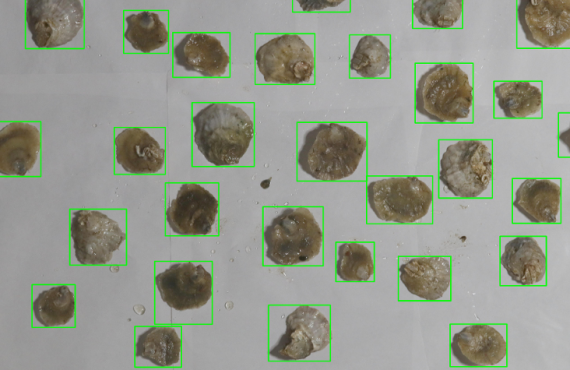

Check the full recording of the webinar “Enhancing oyster production with artificial intelligence & new protocols” (28 October 21) here:

AquaVitae´s webinars have been running since January 2021. They are avaliable here.